Professional manufacturers of traffic safety products with 28 years

Whatsapp:008618662728327Language:

English

English

Professional manufacturers of traffic safety products with 28 years

Whatsapp:008618662728327Language:

English

English

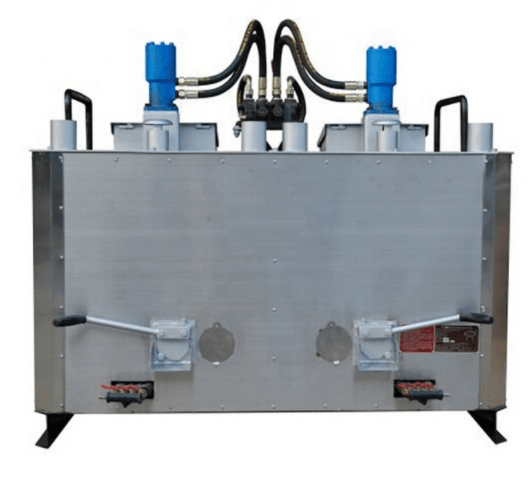

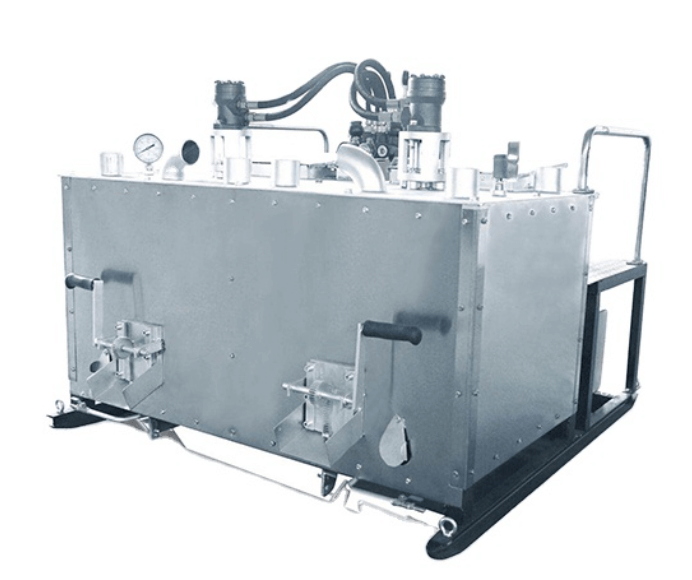

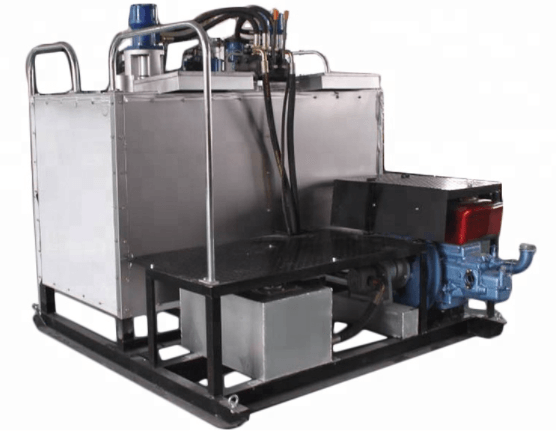

High Efficiency Double Cylinder Hot Melt Machine for Heating Manual Pushing Marking Liner

| engine | 15PS water cooled diesel engine with electric starting |

| Hydraulic driving method | diesel engine drive the stirring shaft to operate through gear pump,multipath hydraulic control valve,overflow valve and hydraulic motor. |

| Hydraulic oil tank | capacity:70L , use 68# hydraulic oil |

| Heating system | liquefied petroleum gas tank supply gas to energy-efficient burner,50kg gas tank is recommended.heating temperature is adjustable,it can range from 0-300 degree centigrade. |

| Melting cylinder | it has enough intensity and reasonable obdurability which make it has good effect of heat transfer. It can accommodate 1200kg hot melt paint (about 48bags). |

| Thermometer | it adopt heat transfer oil as medium which make it heat-resisting ,shock-resistant and more accurate. |

| Operation method | the stirring shaft inside each cylinder can turn clockwise and anticlockwise,which controlled by manual multipath control valve. |

| Outline shape | it is made of double layer stainless steel plate with the advantages of high intensity,high temperature resistance and oxidation resistance. |

| Safety device | multiway control valve has special protection device to prevent the equipment from damage caused by incorrect or rough operation. |

| Size and weight | 1800 (L) ×1830 (W)×1630 (H) mm 7.2CBM 1100kg |

1) Advanced heating, heat preservation, ignition and temperature control not only achieve a great performance of fast melting material, high quality melt and good insulation, but also improve the convenience and safety of the operation greatly.

2) Simplify hydraulic stepless transmission design for easy operation and maintenance; moreover, the protection device prevents the equipment from damage due to the incorrect or rough operation.

3) Unique feeding mechanism design to avoid happening of bad feeding such as missing,blocking, hard operation or easy damage;

4) The inside structure of the equipment is processed by hot galvanizing for anticorrosion. External with 304 stainless steel or high temperature resistant surface coating let the equipment solid, durable and good looking.